Products

RA Series

The RA-Series comprises discrete-direct-purge mercury analyzers, which employ the method of Reducing Vaporization technique for mercury analysis. This technique is also commonly termed as Vapor-Generation or Hydride-Cold-Vapor. In many parts of the analytical world, this technique of Reducing Vaporization – Cold Vapor Atomic Absorption Spectroscopy (CVAAS) is still widely used for mercury measurement. It is also one of the earliest methods that were adopted by EPA and other regulations in their analytical methodology procedure.

Methods

USEPA 245.1 | USEPA 245.2 | USEPA 245.5 | 7470A | 7471B | ASTM D 3223-17 | EN-1483 | APHA 3112 | JIS K0102 | ISO 12846 and more

- New Release 2D Animation - Top 3 Advantages Of Discrete Direct Purge Technique

Cold Vapor Atomic Absorption Spectroscopy (CVAAS)

Which type of detector should I choose?

Reducing Vaporization can be used with either a CVAAS or CVAFS (Cold Vapor Atomic Fluorescence Spectroscopy). Typically, Cold Vapor Atomic Absorption Spectroscopy (CVAAS) is used for Trace-Level (down to sub-parts-per-billion, ppb) while CVAFS is preferred and dedicated for Ultra-Trace-Level (down to sub parts-per-trillion, ppt) applications. In NIC, we have both products ranges, covering the different needs of our customers:

- CVAFS

- CVAAS

Cold Vapor Atomic Absorption Spectroscopy (CVAAS)

About Reducing Vaporization & How It Works

The basic principle

In a sample solution, both ionic and elemental mercury can be readily measured through the Reducing Vaporization – CVAAS or CVAFS method.

In Reducing Vaporization,

A reducing agent such as Tin (II) Chloride, SnCl2, is added into a sample solution to convert all ionic mercury into elemental mercury.

Purging / Sparging

From here, all elemental mercury will be purged by a stream of purified air (for CVAAS) or argon gas (for CVAFS – without or with Gold Amalgamation).

Measurement

Mercury vapor is transported into the optical path of CVAAS or CVAFS for measurement.

Animation with other subtitles available:

Cold Vapor Atomic Absorption Spectroscopy (CVAAS)

Differences between NIC Discrete-Direct-Purge Reducing Vaporization & Other Reducing Vaporization Techniques

NIC Discrete-Direct-Purge Reducing Vaporization

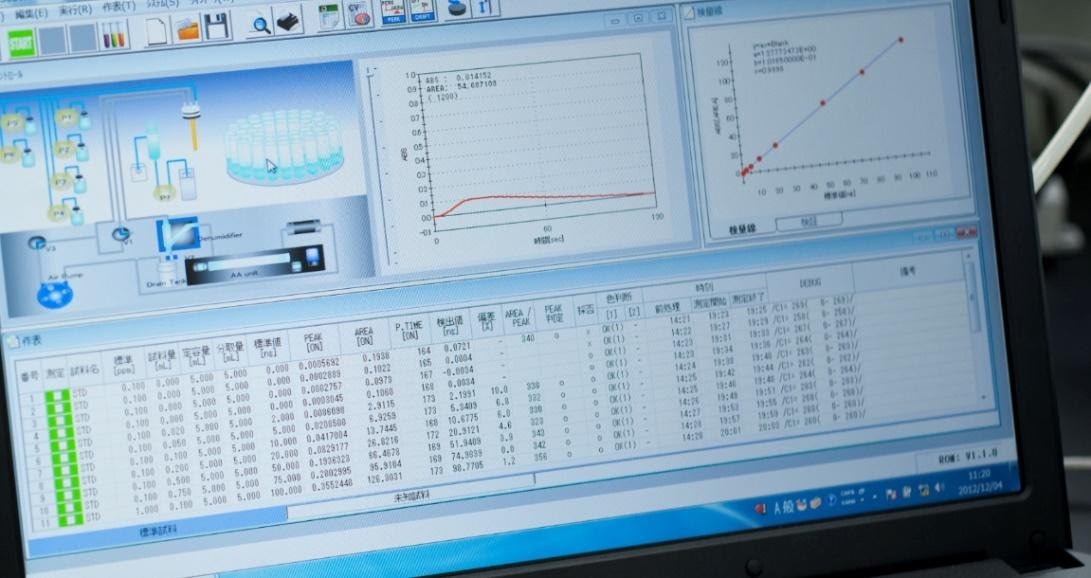

In this technique, the mercury analyzer handles each sample in a Discrete, independent sample tube. Each sample is therefore isolated from surface contact with any other samples in the analytical batch to be measured.

The Direct-Purge technique is then used to extract and transfer the converted Hg0 from each sample tube and into the detector for measurement. Since only mercury vapor contacts the flow path, sample-to-sample memory effects and carryover from over-range samples are virtually eliminated.

How It Works:

- First, reductant (SnCl2) is automatically added into the sample tube containing the acid-digested sample solution. The sample tube is sealed, leaving a closed-loop flow path to the detector.

- The carrier gas is introduced to sparge (or purge) the solution, releasing the elemental mercury vapor from the solution and into the flow path, which then flows directly into the detector for measurement.

Advantages

- Almost no sample-to-sample carryover or memory effect

- Carryover from over-range samples is greatly reduced

- Discrete technique only needs 200-300uL of reagent per sample

- Reduces hazardous mercury wastes to less than one liter per full day of operation

- Filtration of samples not required, as Direct-Purge technique can handle particulates in samples with no issues

Other Reducing Vaporization Techniques

- Commonly based on Flow-Injection or Continuous-Flow Techniques to introduce the full sample solution into the system to complete the chemical reaction for the analysis.

- The acidic sample solutions and reductant (SnCl2) enter the system via pump tubing with peristaltic pumping, which must be replaced often.

- Chemical reduction begins when both the sample solution and reductant are mixed, reducing Hg2+into Hg0, within a continuous flow of reagents.

- Prior to the detector, the liquid-gas phase separator or membrane separation device is needed to remove the liquid, allowing the Hg0gas to enter the detector.

Mercury is well-known for its strong affinity to absorb onto different materials and its high solubility in acidic reagents.

After the digestion and oxidization procedure, samples are usually very acidic. The acidic sample solutions and reductant, SnCl2, enter the system via pump tubing with peristaltic pumping. The acidic sample leaves a residue on the inner surface of pump tubing, creating possible active sites for mercury absorption from current mercury, which is easily passed on to the following samples.

Such phenomenon is inevitable with this technique and commonly exhibits as what is called the mercury memory-effect, experienced by many lab analysts. This effect is especially significant and severe when analyzing samples of varying mercury concentration levels.

Large multi-liter carboys of hazardous waste are produced daily from such flow-based techniques, creating the need for expensive waste disposal. Reduction of hazardous mercury wastes should be a priority for all mankind, and it is a priority of the Minamata Treaty.

Is Wet-Chemistry Cold-Vapor Technique Measuring Total Mercury?

Applications of RA-Series

RA-Series mercury analyzers can be used to analyze

-

drinking water

- industrial wastewater

- river water

- lake water

- seawater

- rain-runoff

- Post-acid-digested Solid Sample Solution

Talk to Us about your applications.

Industries & Application

FAQs

Typically, Cold Vapor Atomic Absorption Spectroscopy (CVAAS) is used for Trace-level (down to sub-parts-per-billion, ppb) while Cold Vapor Atomic Fluorescence Spectroscopy is preferred and dedicated for Ultra-Trace-Level (down to sub-parts-per-trillion, ppt) applications.

Read more about the NIC CVAFS Mercury Analyzer:

RA-4300FG+ | PE-1000 | WA-5F | AM-6F

Yes, all NIC products are either CVAAS or CVAFS. Check out the individual product pages for further information.

The sample required for analysis in all NIC mercury analyzers is tiny. Thus, for a solid sample, it is important to ensure the sample’s homogeneity. It is crucial for liquid samples that the sample integrity is well-kept and protected, especially volatile samples like Naphtha, gas condensate and other liquid petroleum-based samples.