Products

MA Series

What is MA-Series?

Highly regarded due to its ease of use, MA-Series comprises two different direct mercury analyzer models, namely the MA-3000 and MA-3 Solo. Both models utilize the analytical techniques of Direct Thermal Decomposition – Gold Amalgamation – Cold Vapor Atomic Absorption Spectroscopy (CVAAS) to measure total mercury in solid, liquid or gaseous sample matrices.

Quick Facts

About Direct Thermal Decomposition

is also known as the Direct Combustion Technique or Direct Mercury Analyzer in the industry.

NIC superiority on knowledge, experiences and know-how on Direct Thermal Decomposition dates back to more than 40 years.

Direct Mercury Analyzer. Thermal Decomposition. CVAAS.

Challenges in Mercury Analysis

- Conventional methods of measuring mercury present analytical challenges and is often viewed as burdensome by analysts.

- Due to mercury’s unique properties, measurement is a tedious process involving the use of multiple acids for sample decomposition and extraction, and the long duration of sample pre-treatment.

- The lengthy process and high volatility of mercury can easily lead to data uncertainty due to the inevitable loss of analyte or cross-contamination of mercury.

- Often, in mercury measurement, it is hard to achieve good results in the recovery of Quality Control (QC), spike standard, accuracy, and precision.

- Hence, MA-Series Direct Mercury Analyzer is our customers’ top choice for a mercury analyzer to solve their common problems faced on analytical work.

Direct Mercury Analyzer. Gold Amalgamation. CVAAS.

Benefits of NIC MA-Series

Despite the challenges, direct mercury analysis is one of the most widely accepted alternatives to measure mercury, and NIC MA-Series is built just for that.

REDUCE workflow bottleneck

- Users can measure mercury in solid, liquid and gaseous samples (Gas tube) directly

- Versatile to accommodate different laboratories' requests or research needs

NO tedious wet chemical sample pre-treatment

- Short turnaround time for results

- Improve lab productivity

HIGHLY accurate and precise results

- Minimize sample preparation handling error

- Uses Direct Thermal Decomposition technique, unlike the Wet-Chemistry Cold Vapor technique

LOWER operational cost

- No sample preparation so high purity acids and oxidizing agents are not required

ECO-friendly

- No chemicals used, eliminate hazardous waste disposal

EASY to use

- Anyone with basic training can operate MA-Series as it is operator-independent

Direct Mercury Analyzer. Thermal Decomposition. Gold Amalgamation.

Operating Principle at A Glance

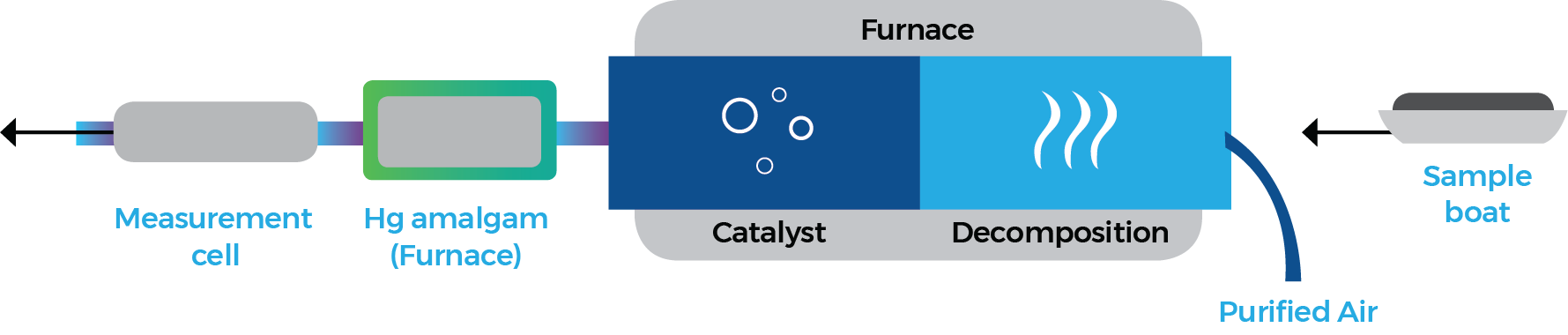

The desired sample is loaded into the sample boat. The sample boat will be transferred into a sample heating furnace where the sample is heated at a high temperature according to the selected method. The sample will be decomposed, and all forms of mercury compounds will be released into its elemental gaseous form.

Gold amalgamation

The released vapor will pass through the mercury collector tube, where the elemental form of mercury will be trapped onto, forming an amalgam with the coated gold layer. This steps removes interferences

CVAAS Measurement

When this thermal decomposition sequence is completed, the mercury collector tube is heated to liberate purified and concentrated pure mercury gas into the measurement cell, mercury is measured by CVAAS at the wavelength of 253.7 nm.

Applications of MA-Series

MA-Series mercury analyzer can be used to analyze:

- foods

- biological specimen

- medicines

- fertilizers

- animal feeds

- electrical and electronic equipment materials

- resins

- coal

- ores

- waste oil

- waste fluids

- soil

- sludge

- petroleum samples

- crude oil

- naphtha

Explore your applications at our Application Data Centre

Industries & Application

FAQs

Direct Thermal Decomposition is a technique used by the NIC MA Series where samples are decomposed to release all forms of mercury. All mercury species are thermally decomposed under catalytic conditions to elemental mercury. The elemental mercury is then trapped and concentrated by a step called Gold Amalgamation before being followed by detection by CVAAS.

Gold Amalgamation is a technique used to collect, concentrate and purify elemental mercury. Mercury and Gold share a common affinity and tends to form an amalgam when interacting. An amalgam is an alloy of mercury with another metal.

So, when the mercury analyte is released from the Direct Thermal Decomposition Step, Gold is used to trap, concentrate and purify the mercury to enhance the analysis recovery.

To learn more, check out the complete steps for Direct Thermal Decomposition.

Direct Thermal Decomposition mercury analyzer is also known as Direct Mercury Analyzer. Both refer to the technique of mercury analysis where wet chemical preparation is not needed.

Yes, our MA-series Direct Mercury Analyzer uses Cold Vapor Atomic Absorption Spectroscopy (CVAAS) for detection.

In NIC Direct Mercury Analyzer Series (MA Series), wet chemical preparation is not needed as the process of decomposing the sample to release mercury has been replaced by Thermal Catalytic Decomposition process.

Yes, NIC MA-Series Direct Mercury Analyzer can produce matrix-independent results. Regardless of the sample matrices, calibration and sample measurement are matrix-independent.

Yes, NIC MA-Series Direct Mercury Analyzer can produce a reproducible result. Most of the reproducibility issues that happen are due to errors from manual handling steps during wet chemical preparation. With more than 40 years of experience, NIC has refined the direct thermal decomposition technique to produce excellent reproducibility. Find out more about the challenges in mercury analysis and how MA Series overcomes it.

Yes, all NIC product software works well with the latest version of Windows operating system (OS).